-

Injectie het Vormen de Diensten

-

De plastic Injectie het Vormen Dienst

-

Het dubbele Geschotene Injectie Vormen

-

precisieinjectie het vormen

-

Het enige Geschotene Injectie Vormen

-

Overmoldingsinjectie het Vormen

-

oem injectie het vormen

-

tussenvoegselinjectie het vormen

-

Elektronikainjectie het Vormen

-

Siliconeinjectie het Vormen

-

De Dienst van het matrijzenafgietsel

-

RecebDe cliënt wil u hun product produceren omdat zij met de resultaten met uw vroegere productie blij waren.

RecebDe cliënt wil u hun product produceren omdat zij met de resultaten met uw vroegere productie blij waren. -

SeanGoed groepswerk – goede leveranciers, snelle acties en goede mensen die aan beide kanten…. samenwerken Dank u.

SeanGoed groepswerk – goede leveranciers, snelle acties en goede mensen die aan beide kanten…. samenwerken Dank u. -

ChrisDank voor het geven genoeg te reageren, denkt verschillend en vernieuwt met ons – hier opnieuw bij deze gelegenheid om dit die alternatief – veel te vinden van ons in RnD wordt gewaardeerd,

ChrisDank voor het geven genoeg te reageren, denkt verschillend en vernieuwt met ons – hier opnieuw bij deze gelegenheid om dit die alternatief – veel te vinden van ons in RnD wordt gewaardeerd,

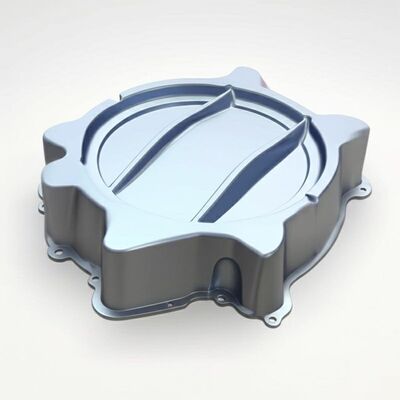

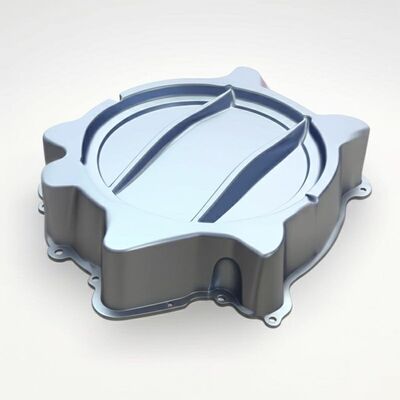

None Finish Injection Molding Service with UG Design Software for ±0.01mm Tolerance Precision

Contacteer me voor vrije steekproeven en coupons.

WhatsApp:0086 18588475571

wechatten: 0086 18588475571

Skypen: sales10@aixton.com

Als u om het even welke zorg hebt, verstrekken wij de online-Help van 24 uur.

x| Equipment | CNC, EDM, Wire-Cutting, Etc. | Application | Injection Molding Parts |

|---|---|---|---|

| Runner | Hot Runner\ Cold Runner | Package | Suitbale Safe Packaging |

| Product Material | Plastic | Surface Finish | Matte, Glossy, Textured, Painted |

| Finish | None | Color | Black Customized Color |

| Markeren | None Finish Injection Molding Service,UG Design Software Injection Molding Service,±0.01mm Tolerance Injection Molding Service |

||

Product Description:

Our Injection Molding Services provide high-quality and precise manufacturing solutions tailored to meet the diverse needs of various industries. Specializing in both Thermoplastic Molding Service and Thermosetting Molding Service, we offer versatile injection molding techniques that ensure superior product performance and durability. Whether you require intricate components or large-scale production runs, our Injection Moulding Service is designed to deliver exceptional results efficiently and cost-effectively.

We work with a wide range of plastic materials, leveraging the inherent advantages of plastic to create parts that are lightweight, strong, and versatile. Our expertise encompasses the use of both hot runner and cold runner systems, allowing us to optimize the molding process based on the specific requirements of each project. The selection of runner type plays a crucial role in minimizing waste, reducing cycle times, and improving the overall quality of the molded parts.

Surface finish is a critical aspect of our injection molding process. We offer several surface finish options including matte, glossy, textured, and painted finishes to meet aesthetic and functional demands. Whether you need a sleek glossy surface for consumer products, a durable textured finish for enhanced grip, or a custom painted finish for brand differentiation, our services can be customized to achieve the desired look and feel.

Our design capabilities are supported by industry-leading software platforms such as UG (Unigraphics), Pro/E (Creo), AutoCAD, and SolidWorks. These powerful design tools enable us to create highly detailed and accurate 3D models, perform simulations, and optimize mold designs before production begins. This ensures that every component we produce meets stringent quality standards and fits perfectly within your assembly or application.

Our Thermoplastic Molding Service is ideal for products requiring flexibility, impact resistance, and recyclability. We mold a variety of thermoplastic materials, adapting processing parameters to suit specific material properties and product specifications. On the other hand, our Thermosetting Molding Service is perfect for applications demanding superior heat resistance, dimensional stability, and mechanical strength. By expertly handling both thermoplastic and thermosetting materials, we provide comprehensive injection molding solutions for a wide spectrum of applications.

Applications of our injection molding services span numerous industries including automotive, electronics, medical devices, consumer goods, and industrial equipment. We manufacture injection molding parts that serve functional, structural, and aesthetic purposes, ensuring that each part delivers reliable performance in its intended environment. Our commitment to quality and precision guarantees that every molded component meets customer expectations for durability, fit, and finish.

Choosing our Injection Moulding Service means partnering with a company dedicated to innovation, quality, and customer satisfaction. From initial concept and design through prototyping and full-scale production, we provide end-to-end support to bring your plastic part ideas to life. With advanced molding technologies, skilled technicians, and comprehensive quality control processes, we ensure your products are manufactured to the highest standards.

In summary, our Injection Molding Services combine advanced design software, diverse material expertise, and flexible runner systems to offer superior thermoplastic and thermosetting molding solutions. With multiple surface finish options such as matte, glossy, textured, and painted, we cater to both functional and aesthetic requirements. Trust us for reliable injection molding parts that fulfill your application needs with precision and excellence.

Technical Parameters:

| Equipment | CNC, EDM, Wire-Cutting, Etc. |

| Tolerance | ±0.01 Mm To ±0.1 Mm |

| Surface Finish | Matte, Glossy, Textured, Painted |

| Mold Life | 300,000-500,000 Shots |

| Product Material | Plastic |

| Color Options | Custom Colors Available |

| Finish | None |

| Application | Injection Molding Parts |

| Color | Black Customized Color |

| Runner | Hot Runner\ Cold Runner |

Applications:

OEM Injection Molding Services are designed to meet diverse industrial needs with exceptional precision and quality. Certified under ISO90001, our services guarantee adherence to stringent quality standards, ensuring reliable and consistent production. With a minimum order quantity (MOQ) of just 1 set, clients have the flexibility to initiate projects of any scale, making it ideal for prototyping as well as full-scale manufacturing.

Our injection molding services are widely applicable across various occasions and scenarios, including the production of complex plastic components where high accuracy and tight tolerance are critical. With tolerance levels ranging from ±0.01 mm to ±0.1 mm, we cater to industries requiring detailed and precise molding, such as automotive parts, consumer electronics housings, medical devices, and packaging solutions.

We offer customization in color, with black as a standard option and a variety of custom colors available to meet specific branding or design requirements. Our advanced equipment, including CNC machines, EDM, and wire-cutting tools, ensures high-quality mold fabrication and finishing. Customers can choose between hot runner and cold runner systems depending on their product design and production efficiency needs.

Packaging is handled securely using metal pallets to ensure safe transportation and storage of the molded parts. Our delivery time ranges from 45 to 50 days, balancing speed with meticulous quality control. Payment terms are flexible with T/T accepted, and pricing is negotiable to suit diverse budgetary needs.

In addition to injection molding, we provide complementary manufacturing processes such as Thermoforming Service, Plastic Extrusion Service, and Thermosetting Molding Service. These services broaden the scope of material and product customization, allowing clients to select the best forming method for their specific application. Our supply ability stands at 10 sets per month, enabling consistent and reliable delivery for ongoing production demands.

Whether you require single prototype molds or full production runs, OEM Injection Molding Services offer a comprehensive solution tailored to your manufacturing challenges, supported by industry-leading technology and quality assurance.

Customization:

Our OEM Injection Molding Service offers comprehensive product customization tailored to your specific needs. Certified with ISO90001, we ensure top-quality standards throughout the manufacturing process. With a minimum order quantity (MOQ) of just 1 set, we provide flexible options suitable for both small and large scale production.

We specialize in Thermosetting Molding Service and Injection Molding Service, utilizing advanced KLM Tooling Base technology to deliver durable molds with a life span of 300,000-500,000 shots. Our supply ability is 10 sets per month, ensuring timely delivery within 45-50 days.

Pricing is negotiable to meet your budget requirements, and we accept payment terms via T/T for your convenience. All products are securely packaged using metal pallets and suitable safe packaging to guarantee safe transit and handling.

Volume production is available, and we offer a wide range of custom color options to perfectly match your design specifications. Trust our Thermosetting Molding Service and Injection Molding Service to provide reliable, high-quality injection molding solutions tailored to your business.